SPECIALIZED SERVICES

Oil FILTRATION

EXTENSION

OF LIFE

COMPONENT PROTECTION

STOP TIME

REDUCED

INCREASED autonomy and power of the injection SYSTEMS

PROBLEMS GENERATED BY THE LACK OF MICROFILTRAGE

CONTAMINATED HYDRAULIC SYSTEM

Pump and valve failures;

Loss of efficiency caused by internal leaks;

Unnecessary stoppage of the equipment;

Premature wear in the service life;

Excess oil change

CONTAMINATED DIESEL

Increased consumption;

Premature failure of pumps and injectors;

Unnecessary equipment stops.

MICROFILTRATION

Microfiltration extracts solid contamination from fluids and extends the life of your equipment. Using Australian high technology, the filter elements record depth filtration.

Each filter element has the capacity to retain approximately 900 grams of contaminants, in addition to removing sludge from the fluid.

EXTENDING LIFE

COMPONENT PROTECTION

STOP TIME

REDUCED

INCREASED AVAILABILITY OF HYDRAULIC AND LUBRICATION SYSTEMS

PROBLEMS GENERATED BY THE LACK OF MICROFILTRAGE

CONTAMINATED HYDRAULIC SYSTEM

Pump and valve failures;

Loss of efficiency caused by internal leaks;

Unnecessary stoppage of the equipment;

Premature wear in the service life;

Excess oil change

CONTAMINATED OIL

Increased consumption;

Premature failure of pumps and injectors;

Unnecessary equipment stops.

HIGH EFFICIENCY FILTERING SYSTEM

FILTERING ELEMENT FM02

THE BEST TECHNOLOGY

OF AUSTRALIAN FILTERING FOR YOUR EQUIPMENT

The filter element of FTA Brasil can be applied to Diesel or Hydraulic oil, ensuring total cleaning of these fluids.

Absolute filtration in 2 micron particles. Beta Ratio * (2micras) = 300 EQUIRES 99.6% EFFICIENCY

* certified by Southwest Research Institute - SWRI.

DEPTH FILTERING

For deep filter media types, the fluid must take indirect paths through the material that forms the filter media. The particles are deposited in the labyrinth-shaped openings throughout the filter medium.

Because of its construction, a deep type filter medium has many pores of various sizes. Depending on the pore size distribution, this filter medium may have a high particle capture range with small sizes.

OIL ANALYSIS

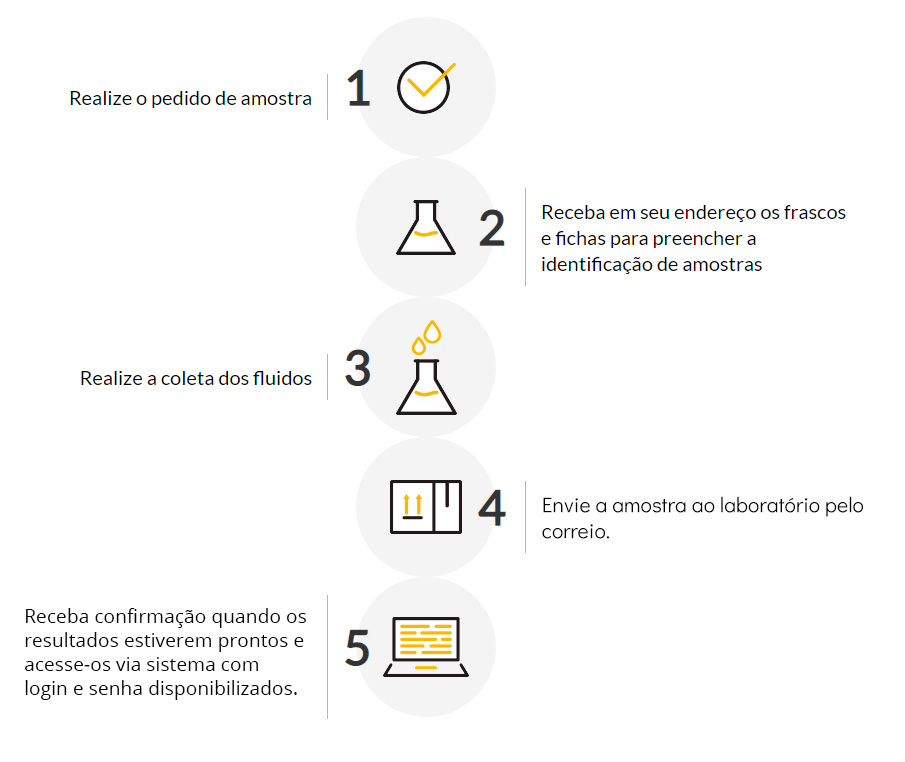

Performing fluid analysis is a predictive maintenance practice that helps the operation to gain performance.

You can order analysis directly with POC Filters.

This technical support provides an indication of risks, possible failures and information about the general condition of your equipment.

The POC Filters Fluid Analysis is performed in an independent laboratory specialized in maintenance. Veja como funciona o processo:

WHY PERFORM PREDICTIVE MAINTENANCE?

Oil analysis is a predictive maintenance technique that, along with the use of filters, complements the maintenance plan and can indicate current and future equipment problems.

By knowing more about the composition of lubricating oils and other fluids, you will be able to know which components are suffering from wear or contamination, and can schedule interventions and repairs.

Make detailed studies with specialized laboratories and increase the profit of your operation.

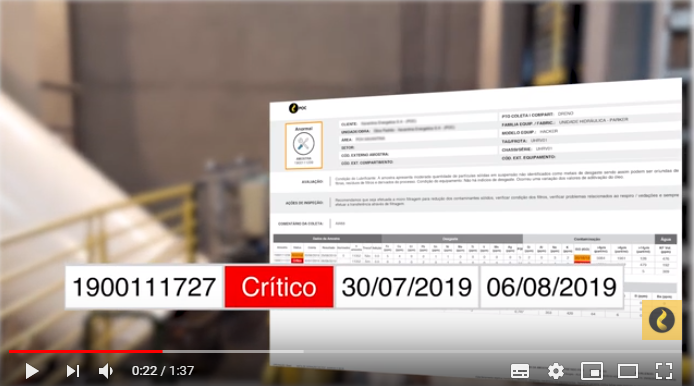

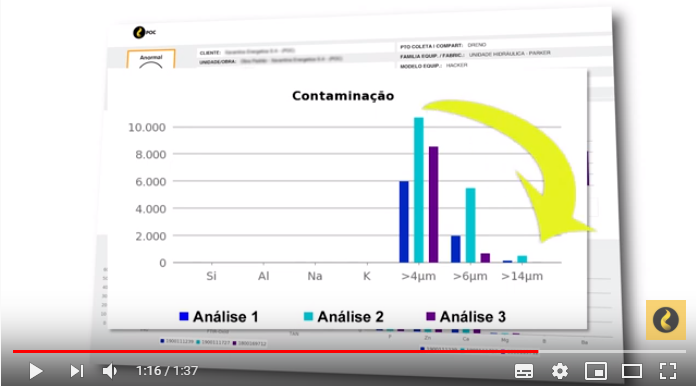

In this video you follow a case study with analysis and filtering of hydraulic oil carried out in a PCH - Small Hydroelectric Power Plant. After performing an oil analysis, the customer noticed a large amount of contaminants in the sample results.

To solve the problem, we carry out oil microfiltration and cleaning the hydraulic tank.

We initially used this microfiltration equipment to transfer the oil.

Later, we opened the tank where contamination was found at the bottom of the compartment. It is worth noting that, in situations of oil tank cleaning, the bottom of the tank, that is, this last oil blade must be discarded. This avoids saturation of filtration equipment.

After cleaning the tank it is time to put all the oil back in and take a new sample for analysis. Comparing the results of the oil analysis, a great decrease in contaminants was noticed.

First report of the Hydraulic Oil Analysis and Filtration case study

According to the Hydraulic Oil Analysis and Filtration case study report

Por meio do monitoramento por análise de óleo foi possível entender e corrigir o problema de contaminação e realizar os procedimentos necessários evitando falhas graves no sistema hidráulico da Usina.

DID YOU KNOW? verified_user

All new oil is already contaminated at the factory and, as a result, the addition of oil can be harmful.

Changing the oil does NOT eliminate contamination.

About 30% of the contaminated oil remains in the lines and sub-compartments.

how oil analysis works at POC Filters

Talk to an expert in oil analysis and filtration and get a free consultation!