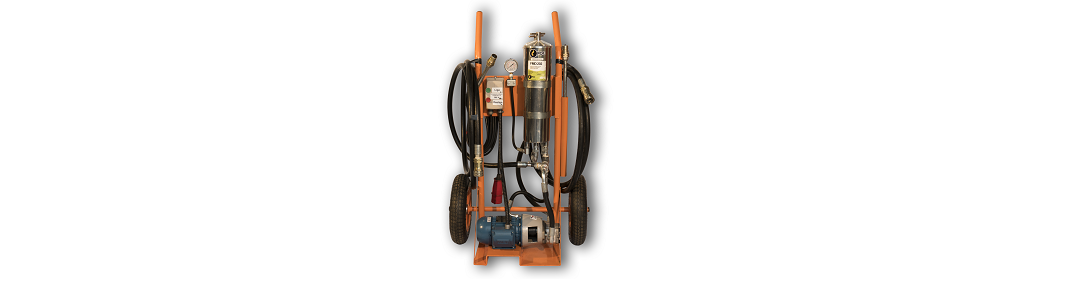

Get to know a hydraulic oil filtering machine in the video:

Oil filtration with mobile units is also known as:

- oil filtration trolley;

- oil dialysis machine;

- trolley for oil filtration;

- mobile oil filtration unit;

- oil filtration unit;

- hydraulic oil filtering machine;

- industrial oil filtering machine;

- oil filtration trolley;

- oil treatment unit;

- mobile oil filtration system.

See a case study with analysis and microfiltration of used oil

See a case study with new oil analysis and microfiltration

Oil and Filtration

Hydraulic oil plays a fundamental role in the perfect functioning of machinery and equipment. The fluid is responsible for lubricating and ensuring the correct movement of the parts. No wonder, on many occasions it is even compared to the bloodstream when talking about human beings.

However, for everything to work as expected, it is important that the fluid is free of contaminants, such as microparticles, or excess water. In this context, a hydraulic oil filtering unit or cart is one of the best ways to avoid unnecessary headaches, such as:

- Stopped machines;

- Slow performance;

- Low productivity;

- Difficulty of operation;

- Increased maintenance expenses;

- Need for spare parts;

- Accelerated wear of equipment;

It is also worth noting that, in addition to lubricating, hydraulic oil still gives strength to important parts of the system, being essential for daily work in the industry, such as production lines or handling equipment and tools. The use of a hydraulic oil filtering machine, in turn, is the technique that ensures that everything happens as expected.

Meet 2 machine models hydraulic oil filtration:

1 -Oil filter trolley FM 202 T

| Flow rate | 7 L/min |

| Autonomy | 15,000 Liters |

| Motor | ½” cv trif. 220/380V |

| Filtering | 2 microns |

| Qtd elem. filters | 2 |

| Work pressure | 2 to 4 bar |

| Saturation pressure | 6 bar |

| Inlet / outlet hose | 5 meters |

| Particle counter | No |

| Power cable | 10 meters |

| Transport car | Yes |

2 -Oil filtration trolley FMD 404 TC (Particle Counter)

| Flow rate | 14 l/min |

| Autonomy | 60.000 liters |

| Motor | 1cv trif.

220/380v |

| Filtering | 2 microns |

| Qtd elem. filters | 8 |

| Work pressure | 2 to 4 bar |

| Saturation pressure | 6 bar |

| Inlet hose / Exit | 5 meters |

| Particle counter | Yes |

| Power cable | 10 meters |

| Transport car | Yes |

Discover the advantages of a hydraulic oil filtration machine.

A hydraulic oil filter trolley helps to extend equipment life, as well as helping to reduce maintenance costs. This is because it prevents contamination, whether liquid or solid, from causing premature wear of parts, generating unnecessary damage.

As it is a mobile unit, an oil filtering cart can be used for dialysis of various equipment even in the most varied sectors, such as agricultural machinery, transport fleets, mining or construction equipment, and industry, for example.

Industry professionals explain that about 80% of mechanical failures are caused by oil contamination. In this way, the filtration performed by hydraulic oil dialysis acts in a fundamental way, also helping to avoid setbacks.

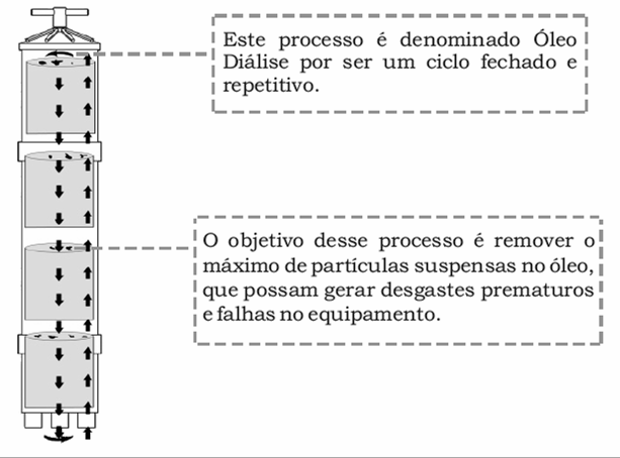

How does dialysis occur with an oil filtering machine?

Hydraulic oil dialysis aims to ensure the vitality of the fluid through microfiltration. The technique gets its name precisely because of the similarity it has with the human body, in which the kidneys cleanse the blood.

Hydraulic oil dialysis removes all the oil contained, separating all impurities, such as water and particles (solid from biological). In other words, it promotes oil hygiene.

How dialysis is done using an oil filtration machine

Once inside the device, the oil passes through a set of depth filtering elements, which are able to retain fine particles. It is important to note that coarse particles can be retained by the filtration system that comes with the engine, but not the finer ones.

It should be noted that, even small ones, such particles can cause great damage if they reach the internal parts of the engine. They help to significantly reduce service life and efficiency, as well as increase the associated operating cost.

When using a machine of hydraulic oil filtration?

Experts from POC Filters affirm that periodic analyzes of the oil must be made so that contaminants that tend to harm the useful life of engines, machines and equipment can be detected.

Read too

The importance of oil analysis in preventive maintenance

Microfiltration reduces costs: understand how

When to perform hydraulic oil microfiltration?

The importance of microfiltration

Microfiltration performed by hydraulic oil dialysis is a process that is capable of removing residues that are not eliminated by the traditional filtration system. The technology offers several advantages, such as:

- Increased machine life;

- Risk prevention;

- Parts wear control;

- Performance improvement;

- Less environmental impact;

Specialized assistance

Do you want to know more about the benefits of hydraulic oil dialysis or need expert help? Then get in touch with POC Filters professionals, who are always on hand to assist in the search for the best solutions for your equipment.