The filtration system is so essential to the machines that some already come from the factory. But working conditions vary widely, and in the case of large machines, it is very common for them to be associated with extreme conditions. Immersed in dense clouds of rock dust – as in mining – and earth in agricultural and forestry machines or soot residues from engine combustion – as in trucks and buses – these assets are requested in countless ways by the weather and by operation itself.

To ensure that the system operates at excellent levels, it is essential to have different filtration systems. Find out below what the difference between a surface filter and a depth filter is and what role each one plays in order to help you achieve your results.

What is surface filter?

We already know that filters for large machines are devices connected to different fluid flow systems: air, lubricant and fuel. Thus, for the filtration process to effectively take place, a filtering medium is necessary, that is, the element that will retain the contaminating particles.

There are several types of material that make up the filter elements: cellulose, polymers, fiberglass, among others. The material depends on the purpose. In filtering lubricants in combustion engines, for example, the use of paper filters is common. In microfiltration, on the other hand, a lot of glass microfiber is used.

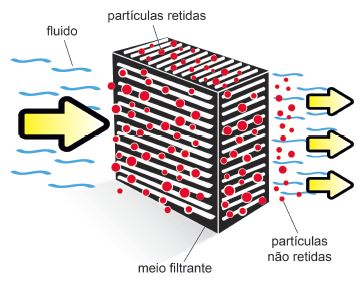

In short, filtration is the process of forcing the passage of a liquid or gas through a porous material in order to remove solids suspended there. If the thickness of the filter medium is similar to the particle size of the particles to be extracted, the process is called surface filtration, since the material is trapped on the filter surface. It is very common to find air filters of this model.

Another typical example of surface filtration is sieves. In this case, the particles are trapped on the surface, forming the cake and allowing smaller particles to pass through the filtering network. There are several formats of surface filters.

What is depth filter?

In the depth filter, in contrast to the surface filter, the solid particles are separated mainly by deposition within the pores of the filter medium, which can consist of:

- A bed of coarser grains (for example, 0.3 to 5 mm deep layer of sand).

- A few centimeters layer of fibers (cartridge filters sealed with resins, for example).

- Leaves a few millimeters thick (for example, filter media made of cellulose).

- A granular support layer to the main filter (pre-coating layer, for example).

In this way, the thickness of the filter medium is at least 100 times greater than the size of the particle to be filtered, when it comes to depth filters. They can be wire cartridges, fiber agglomerates, porous plastic and sintered metals. Therefore, depth filters are constituted by a random network of microfibers of very small granulometry, to the point of retaining microscopic particles. This feature is what ensures that filtering will not only occur on the surface, but in depth through all filter media. This, in turn, can consist of polymers, cellulose or fiberglass, separated or composed.

Thus, in depth filtration, contaminants travel through a kind of “labyrinth” inside the device, becoming entangled in the interlaced microfibers that make up the filtering net. Many depth filters are papers folded in various thicknesses, thus creating a larger filter surface in the same space, when compared to surface filters of equal size.

This is the main advantage of the depth filter, as it will take longer to saturate (clog). In the depth filter, the filter cake is formed, which must be removed periodically to prevent clogging, leaks or failures in the production process. The pie will form until the filter reaches saturation. On some fuel filter models, it is possible to clean a few times with compressed air or diesel oil before needing to change them entirely.

What is the difference between them?

In both cases, the physical processes involved are: direct interception, inertial impact, diffusion and sedimentation. In the surface filter, however, the filtering mechanisms are collision or sifting. In the case of the depth filter, it is entanglement.

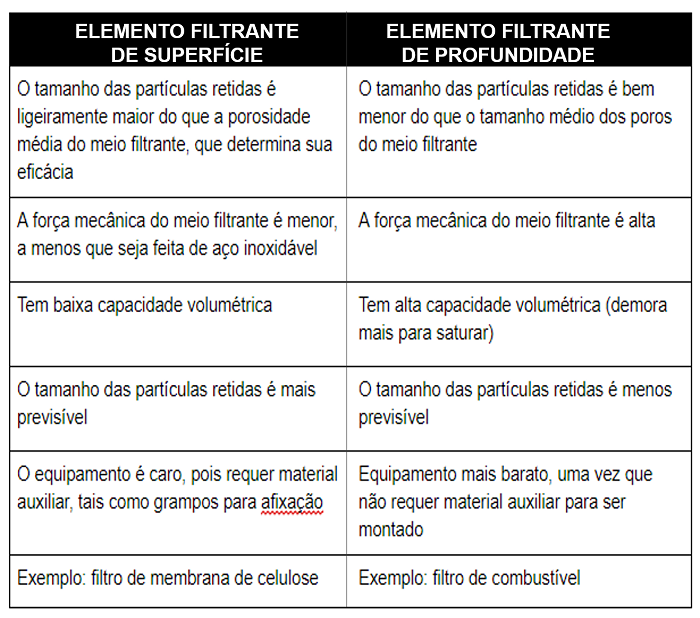

The differences between surface filter and depth filter can be summarized according to the table below;

Although depth filters can always look better, the indication of which filter is best is case by case. As it is a more advanced technology, the application of depth filters is more recommended in the case of systems more sensitive to contamination, such as hydraulic systems. When it comes to air filters, it is very common for a surface device to solve the problem entirely.

Therefore, industrial machines perform heavy and very important tasks to meet the demands of society. To maintain adequate production levels, constant care is required with predictive maintenance, especially with the fluids that nourish these machines. Including filtering systems in predictive maintenance is extremely important both to preserve the vitality of the machines and to ensure that your investment will have the best possible return.

See how different types of filters can help you in this missionconsulting one of our experts. Thank you for your visit!