The ISO 4406 standard is internationally known for establishing technical parameters that express the level of contamination of oils and fluids, as well as specifying the level of oil cleaning required for hydraulic, lubricant and combustion system components.

As we saw earlier, contamination of oils and fluids is a serious problem for the most diverse productive sectors. This contamination, evolving gradually, compromises the useful life of the equipment, requires more frequent changes of parts and fluids, generating higher maintenance costs and even catastrophic failures.

Video – Using the ISO Standard to understand oil conditions

As you can see in the video, due to the size of the gaps in systems (hydraulic, lubricants and combustion) oil contaminating agents such as moisture and microparticles can start premature wear and loss of efficiency, even in small quantities. Thus, to ensure the good performance of machines and equipment, it is essential that regular monitoring of oil and fluid cleaning conditions is carried out.

As you can see in the video, due to the size of the gaps in systems (hydraulic, lubricants and combustion) oil contaminating agents such as moisture and microparticles can start premature wear and loss of efficiency, even in small quantities. Thus, to ensure the good performance of machines and equipment, it is essential that regular monitoring of oil and fluid cleaning conditions is carried out.

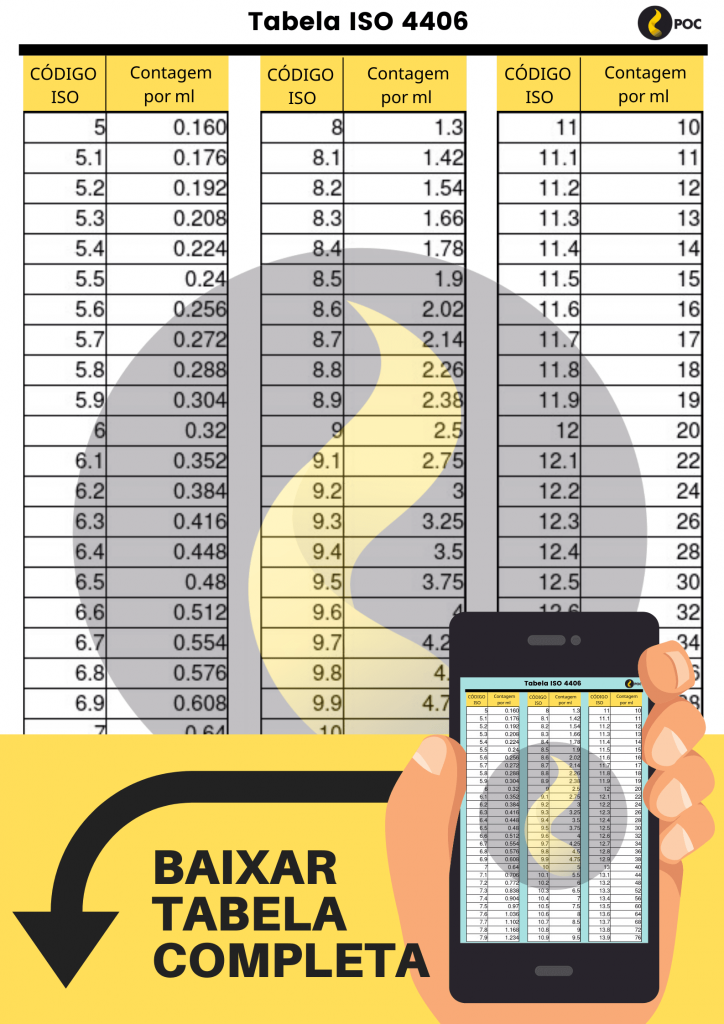

In this sense, standards such as ISO 4406: 1999 are important tools for the monitoring and accurate calculation of the count of contaminating particles present in a given fluid. The ISO 4406 standard consists of a representation guide, in order to simplify the particle count report, converting the quantity found per milliliter of the sample analyzed into a code that measures this value.

We will discuss below the importance of ISO 4406, the most used today. Read our post and learn about the ISO 4406 standard, how it works and how it allows us to identify the levels of contamination in a fluid.

Oil cleaning level x Component Tolerance

ISO 4406 is an internationally known standard that not only expresses the level of contamination of hydraulic oil by particles, but is also used to specify the required level of cleanliness for hydraulic components and systems.

Many manufacturers of hydraulic equipment and bearings specify an optimal level of cleanliness required for their components. Subjecting these components to a fluid with higher levels of contamination may result in a shorter life span for them.

| Component | Code ISO |

| Servo Valve Control | 16/14/11 |

| Proportional Valves | 17/15/12 |

| Pumps / Motors (vane – piston) | 18/16/13 |

| Directional Control Valves | 18/16/13 |

| Pressure Regulators | 18/16/13 |

| Gear Pumps | 19/17/14 |

| Cylinders | 20/18/15 |

| Flux control | 20/18/15 |

| New Lubricating Oil (unused) | 20/18/15 |

Table 1: List of some components and the respective level of ISO contamination required for the oils used in this equipment.

ISO 4406 and particle counting

First, this standard works with three particle size references: 4 micrometers, 6 micrometers and 14 micrometers. These parameters are defined because catastrophic failures in hydraulic systems that occur because of large particles in the oil (14 micrometers or more). While gradual and slow failures, such as wear, are succeeded by the presence of smaller particles (4 to 6 micrometers).

While gradual and slow failures, such as wear, are succeeded by the presence of smaller particles (4 to 6 micrometers).

- First scale: represents the number of particles greater than or equal to 4 micrometers per ml.

- Second scale: number of particles greater than or equal to 6 micrometers per ml.

- Third scale: number of particles greater than or equal to 14 micrometers per ml.

In the table below, it is possible to check the quantity of corresponding particles of each class:

For example, in a code 20/18/15, it means that, in a 1 ml sample, the following were found:

- Between 5,000 and 10,000 particles greater than or equal to 4 micrometers

- Between 1,300 and 2,500 particles greater than or equal to 6 micrometers

- Between 160 and 320 particles larger than or equal to 14 micrometers

Sometimes, we can also come across a banner with “∗” or the “-” sign in the code. Respectively, the first indicates that the sample has an excessive number of particles; the latter suggests that no particle count was required or required.

Degrees of contamination in hydraulic and lubricant systems

Each hydraulic or lubricant system requires that a certain level of oil cleaning is established, to guarantee reliability in performance and avoid unnecessary maintenance and corrective interventions, which benefits productivity and cost savings.

Why understand ISO 4406

Standards such as ISO 4406 help us to realize that an eventual visual inspection of oils and fluids is insufficient to accurately determine levels of contamination.

Knowing well the level of cleaning of the fluids of each equipment, according to the ISO 4406 standard and the manufacturer’s instructions, is a key part for the effective control of contamination and, consequently, for the productivity and success of your business.

See too:

How to Calculate Machine Downtime

If you still want to know more about hydraulic oil contamination and its main causes, read our post on the subject. Caso queira tirar mais dúvidas técnicas ou solicitar uma free consultancy, do not hesitate to contact our specialists.Contact us now.